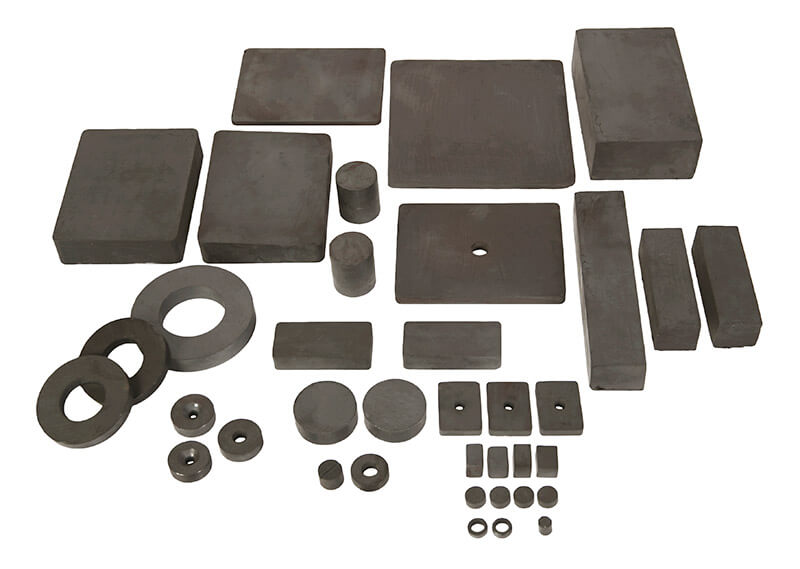

Ferrite magnet: Its main raw materials include BaFe12O19 and SrFe12O19. Manufactured by ceramic technology, the texture of ferrite magnet is relatively hard and it is a brittle material. Due to the good temperature resistance, low price and moderate performance of ferrite magnet, ferrite magnet has become the most widely used permanent magnet.

Ferrite Materials TYPICAL MECHANICAL PROPERTIES OF FERRITE MATERIALS MECHANICAL DATA UNITS THERMAL DATA UNITS Bulk Density 4.85 gm/cm3 Coefficient of Linear Expansion 10.5x10-6 °C-1 Tensile Strength 5.0, 7.0x103 kgf.mm-2, lbs.in-2 Specific Heat (25°) 800 J/kgK. Hard ferrite magnets with 3S (super-small, super-big and super-thin) structure are also producible by wet molding process. The dimensional deviation of hard ferrite magnet is controlled within +/-2% before being machined, and could be controlled within +/-0.10mm after being simply ground by diamond tool. Measurment method for magnetic characteristics FB Series Ferrite Magnet 1. Basic magnetic characteristics of each material The basic magnetic characteristics of magnet materials are measured via the B-H tracer, which consists of electromagnets, gauss meters, flux meters, hole probes, and so on, using special test pieces manufactured through the.

Ferrite magnet is a sintered permanent magnet material composed of barium and strontium ferrite. In addition to strong anti-demagnetization performance, this kind of magnetic material also has the advantage of low cost. Ferrite magnets are hard and brittle, and require special machining processes. The opposite magnet is oriented along the manufacturing direction and must be magnetized in the direction taken, while the same magnet can be magnetized in any direction because it has no orientation, although a slightly stronger magnetic induction is often found on the side where the pressure is the smallest. The magnetic energy product ranges from 1.1MGOe to 4.0MGOe. Due to its low cost, ferrite magnets have a wide range of applications, from motors and speakers to toys and handicrafts, so they are currently the most widely used permanent magnet materials.

Ferrite magnet is divided into permanent ferrite magnet, soft ferrite magnet, and microwave ferrite magnet. Permanent ferrite magnet includes barium ferrite magnet and strontium ferrite magnet. Soft ferrite magnet is divided into manganese-zinc ferrite, nickel-zinc ferrite, magnesium-zinc ferrite, and microwave ferrite includes yttrium ferrite. There are also hexagonal ferrite and so on.

What is the role of ferrite magnet?

1. Magnetic shielding or electromagnetic wave absorption.

Ferrite Magnet Vs Neodymium

2. Isn't ferrite able to withstand high temperatures up to 450 degrees? The general ferrite magnet can only reach 200 degrees.

3. It has an adsorption effect, but the adsorption force is very small, and a bunch of them are conductive, and they are more used in motors.

What is the density of ferrite magnet?

Sintered ferrite magnet: density is about 4.9 g/cm3.

Injection-molded ferrite with a density of about 3.8 g/cm3.

Ferrite Magnet Supplier

Where are ferrite magnets most used?

Ferrite Magnet Gauss

Ferrite magnets are undoubtedly used most in various motors. Starter motors for motorcycles and cars, motors for opening sunroofs. Automatic curtain device, toy motor, etc. If you're looking for top ferrite magnet manufacturer, don't miss out Zhongke magnet factory.